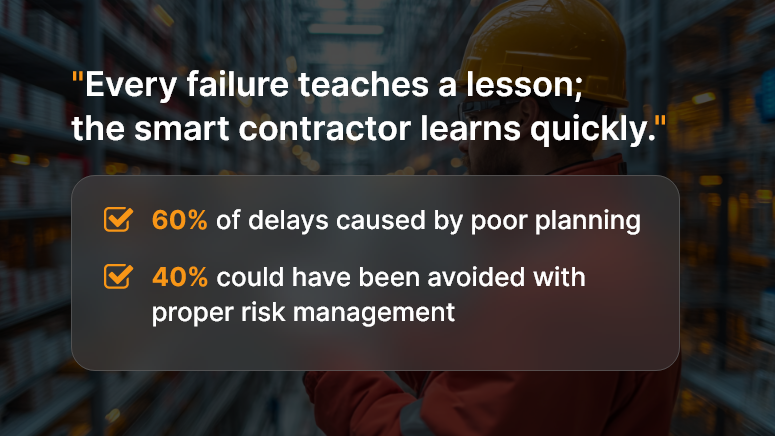

Construction projects are ambitious, high-stakes undertakings that require precise coordination across people, processes, and resources. Yet, even the best-laid plans can falter — resulting in cost overruns, delays, disputes, or outright project failure. While failures are painful, they also provide invaluable lessons that can shape how future projects are planned and executed.

In this blog, we’ll explore the key lessons learned from failed construction projects and provide actionable strategies to avoid repeating these mistakes.

1. Poor Project Planning and Scope Definition

Lesson Learned:

One of the most common reasons for project failure is unclear scope or inadequate planning at the outset. When requirements are vague or stakeholders are not aligned, the project suffers from scope creep, rework, and escalating costs.

How to Avoid It:

- Develop a clear project charter outlining objectives, deliverables, and success criteria.

- Use a Work Breakdown Structure (WBS) to break down activities into manageable tasks.

- Involve all key stakeholders during scope definition to ensure alignment.

- Validate assumptions early with feasibility studies and risk assessments.

2. Ineffective Communication

Lesson Learned:

Breakdowns in communication — whether between owners, contractors, architects, or subcontractors — often lead to misunderstandings, errors, and delays. Many failed projects reveal that critical information was not shared on time, or decisions were not clearly documented.

How to Avoid It:

- Implement a centralized communication platform or Common Data Environment (CDE).

- Standardize documentation formats for RFIs, submittals, and approvals.

- Establish a communication matrix that defines who gets what information and when.

- Conduct regular progress meetings and distribute meeting minutes promptly.

3. Unrealistic Scheduling and Deadlines

Lesson Learned:

Projects often fail when schedules are too ambitious or do not account for contingencies. Unrealistic deadlines create a domino effect — overworked crews, compromised quality, and increased safety risks.

How to Avoid It:

- Use tools like Critical Path Method (CPM) to create realistic schedules.

- Factor in potential risks like weather delays, supply chain disruptions, or labor shortages.

- Build time buffers for complex or high-risk activities.

- Continuously monitor progress against milestones and update the schedule dynamically.

4. Insufficient Risk Management

Lesson Learned:

Unexpected challenges — ranging from design errors and regulatory changes to financial crises—can derail projects that lack a robust risk management plan. Many failed projects ignored warning signs until it was too late.

How to Avoid It:

- Identify risks early during the planning phase and categorize them (financial, technical, environmental, contractual).

- Develop risk response strategies: avoid, mitigate, transfer, or accept.

- Assign a risk owner for each critical risk.

- Maintain a live risk register and review it regularly during project meetings.

5. Financial Mismanagement

Lesson Learned:

Budget overruns are one of the biggest red flags in failed projects. Common causes include poor cost estimation, lack of transparency, and uncontrolled scope changes.

How to Avoid It:

- Use detailed cost estimation techniques (bottom-up or activity-based costing).

- Implement real-time cost tracking systems integrated with the project schedule.

- Allocate a contingency budget of 5–10% to absorb unexpected expenses.

- Regularly review financial reports and adjust forecasts as needed.

6. Lack of Quality Control

Lesson Learned:

In failed projects, quality issues often surface due to rushed timelines, inadequate inspections, or poor workmanship. These errors not only increase costs but also compromise safety and reputation.

How to Avoid It:

- Establish a Quality Management Plan (QMP) before execution begins.

- Conduct frequent inspections, audits, and testing at each project phase.

- Train workers on quality standards and procedures.

- Use digital tools for punch lists and defect tracking to close gaps faster.

7. Ignoring Human Resources and Workforce Management

Lesson Learned:

Labor shortages, unskilled workers, or poor workforce coordination can severely impact productivity. Several failed projects cite workforce mismanagement as a key factor in missed deadlines.

How to Avoid It:

- Forecast labor requirements accurately using resource management tools.

- Provide continuous training and certification for site workers.

- Balance workloads to prevent fatigue and maintain morale.

- Foster collaboration by clearly defining roles, responsibilities, and accountability.

8. Resistance to Technology Adoption

Lesson Learned:

Many construction projects still rely heavily on paper-based processes and outdated systems. This results in errors, delays, and a lack of real-time visibility. Projects that resist digital transformation risk falling behind.

How to Avoid It:

- Adopt construction project management software for scheduling, budgeting, and communication.

- Use Building Information Modeling (BIM) for clash detection and design coordination.

- Implement mobile apps for on-site reporting, safety checklists, and daily logs.

- Leverage drones, IoT sensors, and AI for progress monitoring and predictive insights.

9. Weak Stakeholder Engagement

Lesson Learned:

Ignoring the concerns of clients, communities, or regulators often results in disputes, protests, or costly project shutdowns. Failed projects highlight that stakeholder management is just as important as technical execution.

How to Avoid It:

- Map all stakeholders and assess their level of influence and interest.

- Engage stakeholders early and keep them updated with transparent communication.

- Establish grievance redressal mechanisms for local communities.

- Align project objectives with client and end-user expectations.

10. Failure to Capture and Apply Lessons Learned

Lesson Learned:

Ironically, one of the biggest lessons from failed projects is that teams often don’t document lessons learned. This leads to the same mistakes being repeated across multiple projects.

How to Avoid It:

- Conduct post-project reviews and document lessons learned.

- Share findings across teams and departments.

- Maintain a knowledge repository accessible to all stakeholders.

- Integrate lessons learned into future planning, training, and process improvements.

Conclusion

Construction projects fail not just because of external challenges but often due to avoidable internal missteps — poor planning, weak communication, and inadequate risk management. The good news? Every failure is an opportunity to improve. By learning from past mistakes and adopting proactive strategies, construction firms can reduce risks, protect margins, and deliver projects on time and within budget.

FAQs

1. Why do construction projects fail most often?

Construction projects typically fail due to poor planning, weak communication, unrealistic schedules, financial mismanagement, or a lack of proper risk controls.

2. How can scope creep be avoided in construction projects?

Scope creep can be minimized by clearly defining project scope at the outset, documenting all requirements, and implementing a strict change management process for any modifications.

3. What role does communication play in construction project success?

Effective communication ensures that all stakeholders stay aligned, decisions are documented, and critical information flows without delay. Poor communication often results in rework, disputes, and costly mistakes.

4. How do unrealistic schedules contribute to project failure?

Unrealistic deadlines pressure teams to cut corners, compromise safety, and overlook quality. They also increase stress on workers, leading to mistakes and burnout.

5. What are the best practices for construction risk management?

Identify potential risks early, categorize them (financial, technical, environmental), maintain a risk register, and assign clear responsibilities for monitoring and mitigation.

6. How can contractors avoid budget overruns?

Accurate cost estimation, real-time expense tracking, contingency reserves, and regular financial reviews are essential to prevent budget overruns.

7. Why is quality control so critical in construction projects?

Quality lapses not only lead to costly rework but also compromise safety, compliance, and reputation. Regular inspections and a strong Quality Management Plan (QMP) ensure long-term durability.

8. How can technology prevent construction project failures?

Digital project management tools, BIM (Building Information Modeling), mobile apps, and drones provide real-time insights, reduce errors, and improve collaboration between teams.

9. What’s the importance of stakeholder management in construction?

Active stakeholder engagement ensures transparency, reduces disputes, and aligns project goals with client and community expectations — ultimately preventing resistance and delays.

10. How can companies ensure they learn from past project failures?

By conducting post-project reviews, documenting lessons learned, sharing them across teams, and embedding improvements into future processes, companies build a culture of continuous learning.